Partner

DeFelsko

Surface profile / roughness

Surface profile / roughness

Benefit

What is the benefit of measuring surface profile / roughness?

Steel is often blast cleaned or otherwise roughened prior to painting. The height of the resulting "surface profile" from peak to valley is a critical and decisive factor for the performance of the applied paint and other protective coatings. If the height of the surface profile is too low, it can reduce the adhesion of the coating. If it is too high, the peaks (peaks) may not be adequately covered, leading to premature rusting and often requiring additional paint (and labour costs to apply it) to cover the anchor profile.

Research over the last 15 years has shown that the height of the surface profile is not the only important parameter. Peak density (also known as peak count), the number of peaks in the surface profile per unit area, has been shown to be a critical factor in coating adhesion and corrosion resistance. In fact, studies have shown that peak density can be a better predictor of coating performance than peak-to-valley height.

The height of the surface profile can also be relevant for other industries to quantify the profile height of slip-resistant surfaces and to evaluate the concrete surface profile (CSP) before applying coatings to concrete.

Measurement on metal surfaces

Measures the surface profile on metal surfaces

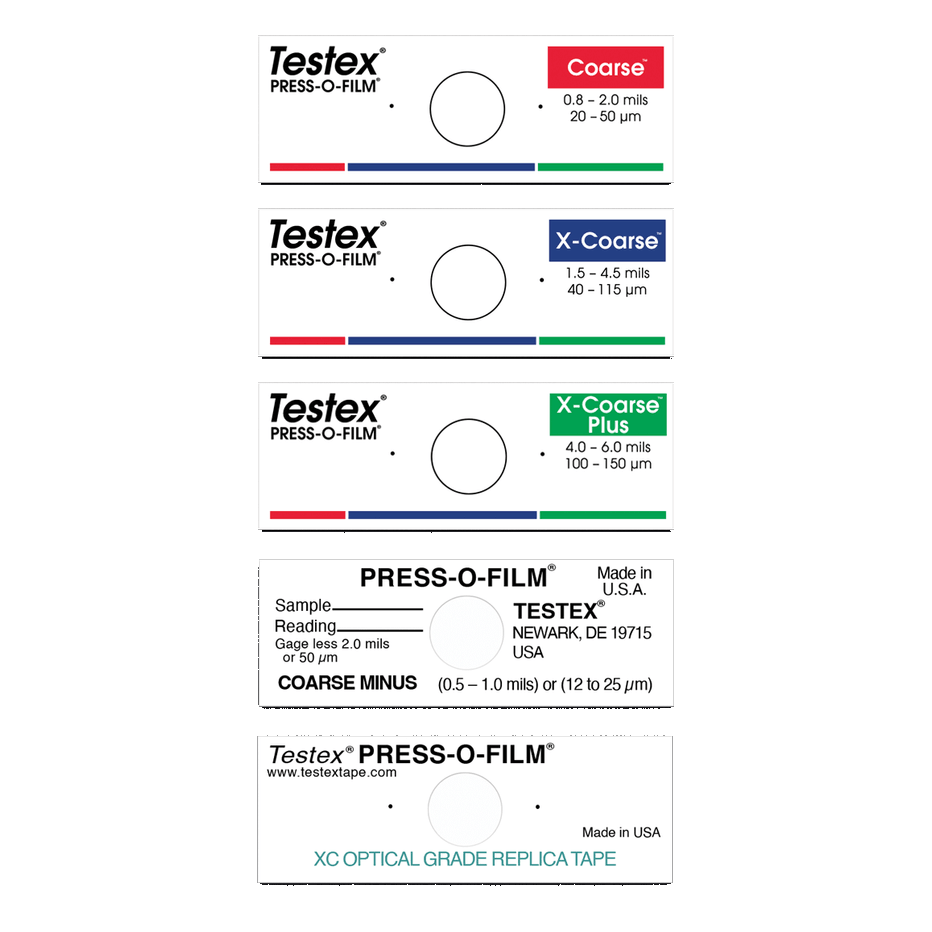

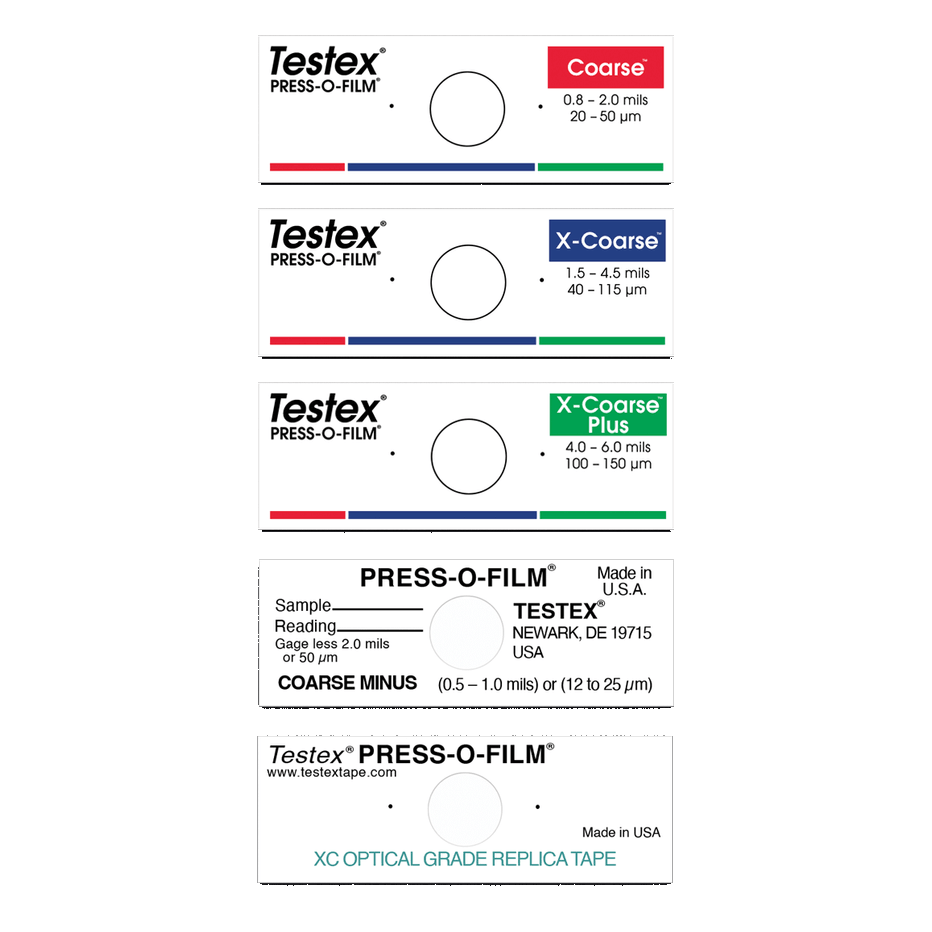

Testex Replica Tape

The Testex Replica Tape measures the surface profile by creating a replica of the surface that can be measured with a micrometer. A simple and proven method whose accuracy and repeatability has been confirmed by numerous independent studies.

Complies with ASME B46, ASTM D4417, ISO 8503-5, NACE SP287, SSPC-PA 17, SP5, SP6, SP10, SP11-87T and others

Measures the surface profile on metal surfaces

Testex micrometer

The Testex Digital Micrometer makes using Testex Replica Tape even easier. It has been specially developed as an optimal tool for measuring replica tapes and makes taking measurements and creating reports easier than ever.

Measurement on different surfaces

Digital surface profile measuring devices for blasted steel, textured coatings and concrete profiles

PosiTector SPG surface profile measuring device

Surface profile gauges use a digital depth micrometer fitted with a fine, pointed probe to measure and record the heights of the surface profile from peak to valley and are used to prepare for the application of coatings.

Conforms to ASTMD4417-B, ASTM D8271 (SPG TS only), AS 3894.5-C (with optional 30° tip), U.S. Navy NSI 009-32, Navy NAVSEA 009-32, US Navy NAVSEA PPI 63101-000, SSPC PA 17, SANS 5772, and others.

Digital replica tape reader for blasted steel and textured coatings

PosiTector RTR H replica tape reader

Digital spring micrometers measure and record surface profile parameters using Testex Press-O-Film™ replica tapes, enabling more accurate peak-to-valley surface profile height measurement for blasted steel and textured coatings.

Conforms to ASTM D4417, ISO 8503-5, NACE SP0287, SSPC-PA 17, SSPC-SP5, SP6, SP10, SP11-87T and other standards.

Digital replica tape reader for measuring and recording 2D/3D surface profile parameters

PosiTector RTR 3D replica tape reader

Digital Replica Tape imagers measure and record 14 common 2D/3D surface profile parameters with Testex Press-O-Film™ Replica Tape. Download high-resolution SDF files for further analysis (advanced models only).

Complies with ASME B46, ASTM D4417, ISO 8503-5, NACE SP0287, SSPC-PA 17, SSPC-SP5, SP6, SP10, SP11-87T and other standards.

Assessment Comparison

Assessment of the surface profile depth generated by blasting by touch and visual inspection

Surface roughness comparison discs

The durable roughness discs contain four or five reference profile types per comparator. You can choose from steel shot, grit/slag and sand.

Complies with standards ISO 8503-1, ISO 8503-2, ASTM D4417-A

Comparison panels for the evaluation of the concrete surface profile (CSP)

ICRI concrete surface profile panels

The International Concrete Repair Institute (ICRI) produces 10 different concrete profiles, which are formed using various surface preparation methods. Each profile has a CSP number ranging from CSP 1 (almost flat) to CSP 10 (very rough; amplitude greater than ¼" [6 mm]).

Conforms to SSPC-SP13/NACE No. 6 -Surface Preparation of Concrete