Partner

Sealed charts and cards for coating tests

Sealed charts and cards for coating tests

- Leneta's sealed charts are made from high-quality, 0.35 mm (14 mil) thick, double-sided coated cardboard produced

- Leneta's sealed cards consist of 0.5 mm (20 mil) thick, one-sided coated cardboard with greater rigidity for more convenient handling.

Both products are equipped with a 100%igen UV topcoat sealedwhich prevents applied varnish from penetrating the paper. The paper contains No optical brightenerswhich can affect instrumental colour measurements.

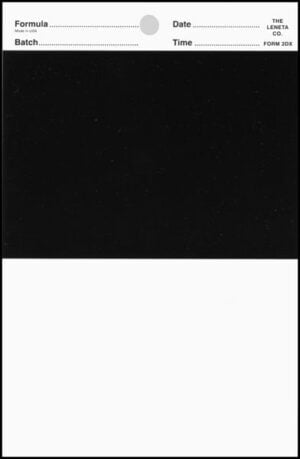

Opacity charts

Opacity chartsalso known as 'hiding power charts' or 'contrast ratio charts', have simple combinations of black and white surfaceswhich are large enough for reflection measurements with wide aperture, and for Visual opacity and colour observations. The black and white test areas are marked with a clear, impermeable top layer sealedwhich prevents the penetration of applied coatings into the paper.

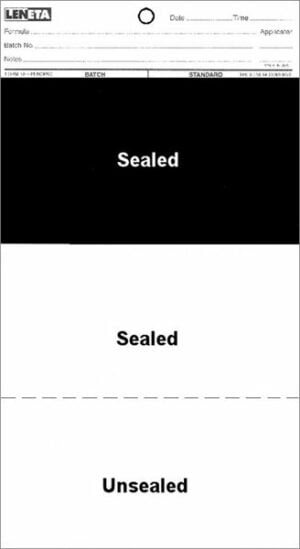

Penopac charts

These Penopac charts (Penetration & Opacity) combine the test areas and functions of a Penetration map and an opacity map. They can be regarded as universal test cards for research and development as well as for quality control. Penopac cards contain both sealed and unsealed areas. The sealed Areas are marked with a clear, impermeable top layer which prevents penetration, while the not sealed Areas with a semi-porous clay coating are provided.

Penetration charts

An important feature of architectural coatings is their ability to create a Uniform appearance on surfaces with varying porosity to preserve the colour. This ability, in which gloss and colour uniformity are specific aspects, is known as Penetration resistance labelled. The adjacent sealed/unsealed areas points for testing the penetration resistance clear conditions with varying porosity represent. In addition to the qualitative visual observations, photometric measurements on the two areas provide objective numerical values.

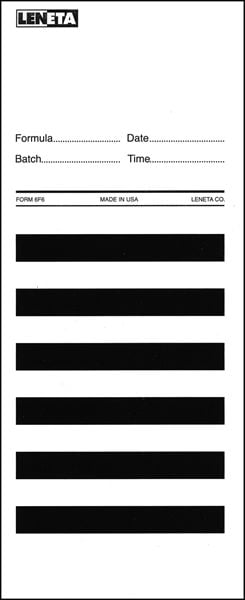

Display charts / Spreading rate charts

These Display Charts use the proven diagonally striped patternwhich have a strong visual impact and emphasise the differences in the opacity of the film. They are therefore often for displaying the opacity through drawdowns or brushouts used. Grey stripes in the form 8H-GW ensure a lower substrate contrast when using coatings with low opacity. The Spreading Rate Charts (Form 8H and 8H-GW) have a Area of exactly 0.1 square metren and become for Brushout opacity tests with certain coating speeds as described in ASTM method D 344.

Opacity - Display charts / Spreading rate charts

Charts of this type combine the large, uninterrupted surfaceswhich are characteristic of opacity cards, with the stripe design a display chart. The larger areas allow Photometric measurements with wide aperture and Visual colour comparisonswhile the striped area for the Comparison and display of opacity is uniquely effective. Spreading rate charts (Forms 12H and 13H-H) have an area of exactly 0.1 square metres and are to be used for the Spreading at certain application rates intended.

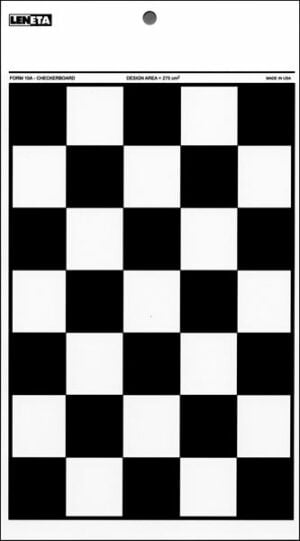

Checkerboard charts / Spreading rate charts

One of the earliest surfaces for testing opacity was linoleum with a black and white chequered pattern. This was soon replaced by Sealed cardboard panels of which the form 10H and 10H-BG Spreading Rate Charts are typical examples. They were developed for the Brushout at certain application rates developed, such as the ASTM method D 344 and the Canadian 1-GP-71, but are also used for Draw down applications like their smaller counterparts, the Form 10A and 10B. The black and grey squares in Form 10H-BG offer reduced contrast for testing coatings with lower opacity.

Brushout cards

The for informal brushout applications developed paper is thicker than normal card paper - 0.5 mm (20 mils) compared to 0.35 mm (14 mils) to achieve a greater rigidity and more comfortable handling to ensure a high level of safety. They are also frequently used for Drawdowns and colourimetric measurements used.

Duplex applicator charts

They were originally developed for the Duplex applicator, a device used for the rapid production of adjacent drawdowns is designed. Today they mainly serve as General colour test cards.