Partner

Leneta

Precision test cards for the coating industry

Special substrates for coating testing

Matt wall charts

Large, matt test surfaces for practical laboratory tests of wall paints that can be Roller or brush be applied.

These charts are labelled with a flat surface coatedwhich in texture and "jaggedness" of a resembles commercially available flat wall paint. The colours can be applied with a brush or roller, ensuring that the colour does not "slide away" during application. The surface is Well sealedso that both Water-based and solvent-based coatings can be applied without the medium penetrating the substrate. The grey stripe offers a lower contrast than black and white charts, which corresponds to the practical nature of large-scale roller and brush application tests.

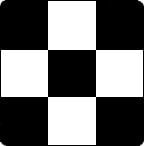

Spray monitors

Self-adhesive opacity labels (Spray Monitor): These are pressure-sensitive labels with a Opacity test sample and one sealed, solvent-resistant surface. They are mainly used for Metal panels where the uniform surface gives no visual indication of the thickness of an applied layer of paint. When the monitor is applied to such a surface, it provides a high-contrast feature that allows the Opacity observed during spray application which means that the Checking the layer thickness made easier is applied. The monitor adheres firmly, regardless of whether it is air-dried or baked, and provides a permanent visual record of the coating thickness. The longer monitors, M71 and M72, enable wedge application with thickness and opacity determination, as described for the spray strips.

Spray strips

Opacity strip for (Spray Strips) OEM coatingsThey are used by industrial coating laboratories, especially in the Automotive industry, is used to set the Measuring the hiding power of spray paints. The strip is covered with Adhesive tape on a steel plate glued and the Test coating sprayed onto create a "wedge" that Thin at one end and thick at the other is. After drying, a spot is determined on the strip that has a Sufficient visual opacity or a contrast ratio of 0.98 and the coating thickness is measured electronically on the steel plate next to this point. Conversely, a spot with a certain thickness is determined on the steel plate and the contrast ratio is measured in the vicinity of this spot.

Release paper

For the production of free films of organic coatings. This paper is Sealed on both sides, one side glossy, the other matt. The shiny side has a silicone coating with a balanced separating effect to prevent excessive Avoid creeping of solvent-based or water-based coatings and at the same time a Easy removal of dried films to enable the test. It is recommended in ASTM D 4708 "Standard Practice for Preparation of Uniform Free Films of Organic Coatings" and can be used to prepare test films for ASTM D 2370 "Tensile Strength of Organic Coatings", ASTM D 1653 "Water Vapour Transmission of Organic Coatings Films" and other free film test methods.

Separation charts

For quick and precise measurements of hiding power. These charts have a unique Surfacewhich easily wetted by water-based or solvent-based paints from which the However, the dried film can be easily removed with adhesive tape can be removed, even if not so easily that undamaged free films are created. The peel-off function enables the exact determination of the Dry film weight on a measured surface by weighing on an analytical balance before and after stripping the film.

Wood, plastic, fibreboard and aluminium-laminated cardboard

In addition to the sealed and unsealed charts and cards, Leneta offers a Variety of materials as standardised substrates on. The materials described here offer a Wide range of absorption, surface and other propertieswhich can be useful when evaluating a coating or stain.

Leneta black glass panels

Black glass is used in the widely referenced, high-precision ASTM method D 2805 and related opacity testing methods. According to the Measurement of the reflectance R0 of the dry film a certain area is scraped off the glass and weighed to determine the propagation rate (spreading rate) or the original Wet film thickness to be determined. R∞ of the colour film is determined by a separate test application. The opacity is then determined using the corresponding Kubelka-Munk equations calculated using the ASTM method.