Optional ...

Your product

TQC Sheen ideal finish analysis software

TQC Sheen ideal finish analysis software

Use the free TQC Sheen Ideal Finish Analysis software to download CurveX, DewCheck, PosiTector 6000 and PolyGloss/SoloGloss data to a computer to analyse the data and print reports.

Stove profiling has never been so easy

Oven profiling is fundamental throughout the coating industry and the latest technological developments can provide production managers and engineers with meaningful information about their production processes.

To guarantee surface quality, it is necessary to collect accurate information about the temperatures to which a coated product is exposed during the oven curing process. Each powder coating has specific curing information (time and temperature values) provided by the coating manufacturers.

To collect temperature information as it is experienced by the product, an oven temperature logger must travel with the products through the oven. This provides a complete in-process journey, profiling the oven temperatures and their performance with real and accurate data.

Information captured by an advanced oven data logger system such as the CurveX can:

- Recognising temperature fluctuations

- Reduce energy costs and save money by increasing the line speed or lowering the oven temperature

- Optimise production processes

- Provides data to prove product quality and fulfil the specification

Reduce time and costs

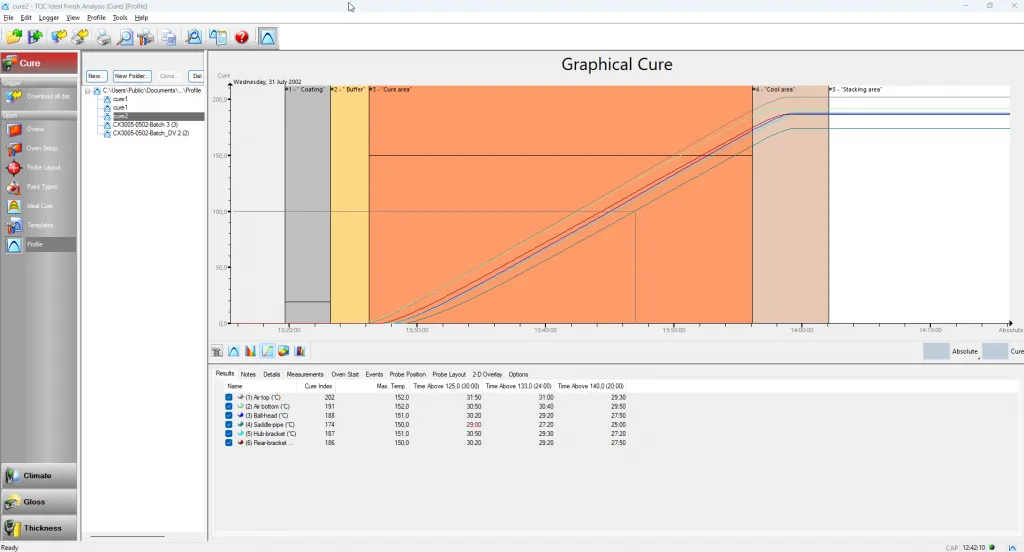

The TQC Sheen Ideal Finish Analysis software, using pre-set ovens and paint types, can combine with the retrieved data to produce a graphical representation and report of the paint curing process.

Such curing insights can lead to a dramatic improvement in production processes. From reducing the time the coated product is in the oven to reducing the oven temperature to achieve a more efficient and safer operation in terms of time and energy costs.

The TQC Sheen Ideal Finish Analysis Software is free of charge.

Ideal Finish Analysis allows the user to set up ovens with separate areas such as curing and cooling and different types of paint with their curing temperatures and times.

Features

- Allows the user to analyse data from different loggers

- Burn-in for the TQC Sheen CurveX logger

- Climate for the TQC Sheen DewCheck

- Thickness for the Defelsko PosiTector 6000 (For the entire PosiTector series, PosiTest AT and PosiTest PC, use the PosiSoft analysis software from DeFelsko)

- Gloss for the TQC Sheen Glossmeter

Additional information

| brand | TQC Sheen |

|---|---|

| Mission | Coating testing, temperature and climate tests, software |

| Industry sectors | Plastics and polymers, !!! Painters Coaters Printers, Industry, Automotive industry |

| Substrates/substances | Wood & by-products, plastics and polymers, metals, aluminium, steel |