Our service

Oven measurements by Novamart AG

Oven temperature data logger CurveX 4

Oven measurements

Novamart AG takes care of your one-off or regular oven measurements on site, e.g. as part of your oven inspection or maintenance. We use our oven temperature data loggers to measure your firing cycles and create detailed reports for you with suggestions for optimisation.

Advantages of oven measurements

- Precise visualisation of the oven temperatures

- Detect deviations

- Recognising and avoiding under- or overheating

- Control of heat distribution

- Discover energy guzzlers/leaks

- Energy optimisation

- Reduction of rejects and repainting

- Save time and money

Several factors must be taken into account to achieve an optimum coating result:

Specific properties of the coating material

Hardness, adhesion or chemical resistance are only achieved after sufficient cross-linking.¹ Each paint has its own stoving process. Refer to the material data sheets of the paint manufacturer for the required stoving conditions.

Correct curing temperature

During the stoving process, both the chemical cross-linking, i.e. the curing of the paint system, and the drying, i.e. the evaporation of volatile paint components such as solvents, take place.

Correct burn-in time

Stoving time always refers to the time in the oven during which the painted object maintains the stoving temperature. However, this so-called holding time is often confused with the dwell time in the oven, which also includes the heating time in addition to the holding time.

Heating speed of the object to be coated

This heating time is heavily dependent on the oven design, the oven occupancy and the geometry as well as the material of the object to be coated. If the actual heating time is not taken into account when determining the dwell time in the oven, this can lead to incorrect curing times and thus to over- or under-firing.

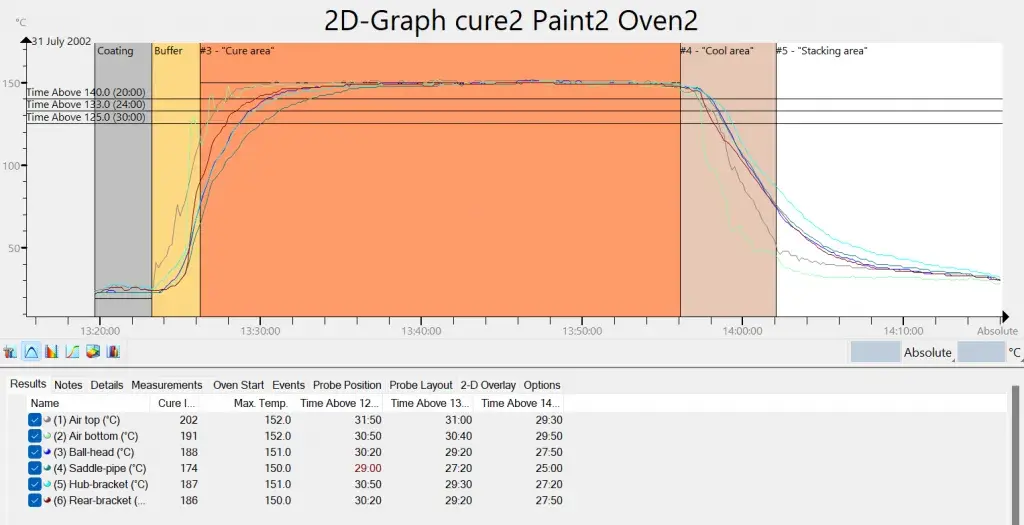

Oven profile stoving diagram

Oven measurements are carried out on the basis of so-called oven curves, which show the temporal progression of the relevant temperatures and the heating rates.

This is achieved on the one hand by constantly monitoring the oven air temperatures during the curing process and on the other by fixing several temperature sensors directly to the surface of an unpainted object. In this way, specific oven curves are obtained for each object to be coated and the individually required dwell time in the oven can be determined.¹

If in doubt, several oven curves must be measured, e.g. for almost empty, half-loaded and fully loaded ovens.¹ It is also advisable to have a traverse with different references or a corresponding profile ready for the oven measurements and to use it for each measurement. This ensures that the material, geometry and position of the coated parts in the oven are accurately reflected in the measurement. Regular measurements also sharpen the eye for the respective production.²

Tips for oven measurements from BESSER LACKIEREN:

- Do not measure the temperatures of the oven air and the object at just one point!

- Record oven curves regularly! (1/4 annual measurement recommended)

- Record new furnace curves after process adjustment! (modification of the system, maintenance of the burners, different loading)

- Always determine the oven curves with the same product carriers, the same components and the identical positions for the temperature sensors!

- Measure the oven curves with a full oven (real conditions)!

Quality assurance and process optimisation

Optimum curing conditions are not only decisive for the quality of a coating, they also enable a reduction in energy consumption and cycle time. In view of rising energy costs and quality requirements for paintwork and coatings, precise knowledge of the temperature both in the curing oven and on the workpiece itself is a quality-critical and, not least, economic criterion.

Our precise oven measurements help you to better understand your coating process, identify possible defects and optimise it according to your requirements and energy efficiency. Contact us today to realise your full potential!